introduce:

Packaging plays a vital role in ensuring product safety, durability and appeal. Polyethylene (PE) heat shrink film is such a revolutionary packaging material. PE heat shrink film is widely recognized for its versatility and adaptability in various industries. This blog aims to provide an in-depth look at the exceptional functionality and diverse applications of this exceptional packaging solution.

1. Excellent characteristics of PE heat shrinkable film:

PE heat shrink film is known for possessing several unique features that make it ideal for packaging applications:

a) Transparency: The excellent transparency of PE shrink film makes the products in the package clearly visible, enhancing its visual appeal.

b) Flexibility: The film has excellent flexibility, allowing the packaging to easily conform to various product shapes and sizes.

c) High tensile strength: PE heat shrink film has significant tensile strength and provides good protection for packaged goods during loading, unloading and transportation.

d) Heat Shrink: When exposed to heat, PE shrink film shrinks seamlessly around the product, creating a tight, durable and tamper-proof package.

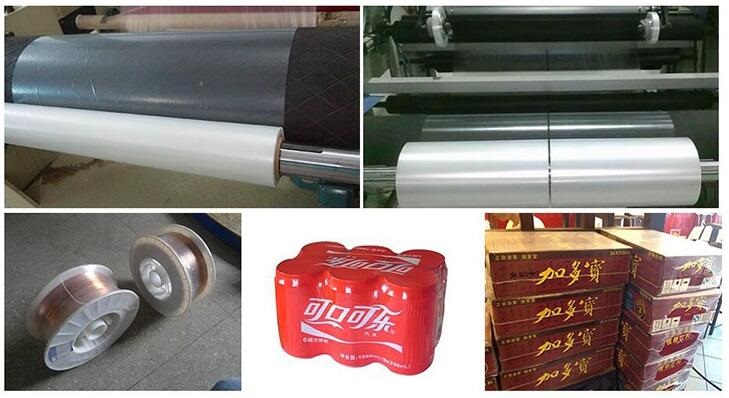

2. Application of PE heat shrinkable film:

a) Food and beverage industry: PE shrink film is widely used in the food and beverage industry because of its ability to preserve freshness and ensure hygiene. It is commonly used to package food products such as meat, poultry, dairy and baked goods, providing an airtight seal that extends their shelf life.

b) Cosmetics and toiletries: PE heat shrink film is ideal for packaging cosmetics and toiletries, including shampoo, lotion and soap. The film is moisture-proof, tamper-proof and UV-resistant, maintaining the integrity of the product and enhancing its visual appeal.

c) Pharmaceutical industry: The pharmaceutical industry relies on the use of PE heat shrink films to secure and protect various medical products, including vials, blister packs, syringes and medical equipment. Its excellent transparency makes labels and instructions easy to read.

d) Electronic products: PE heat shrink film is widely used in the electronics industry. It provides protection against dust, moisture and mechanical damage during transport and storage of electronic equipment, cables and precision electronic components.

e) Industrial products: PE heat shrink film is ideal for packaging and protecting industrial components, automotive parts and machinery during transportation. It is resistant to wear, UV radiation and environmental factors, ensuring safe delivery of goods.

f) Promotional items: PE heat shrink film is often used to bundle promotional items, improve their display and provide an extra layer of protection from handling and shipping.

3. Environmental considerations:

It is worth noting that PE heat shrink film is fully recyclable, and manufacturers are increasingly exploring sustainable options, such as biodegradable and recycled PE films, to reduce their impact on the environment. By embracing these eco-friendly alternatives, the packaging industry can create a more sustainable, greener future.

in conclusion:

PE shrink films have become a versatile, reliable and cost-effective packaging solution across multiple industries. Its exceptional properties, including transparency, flexibility and high tensile strength, contribute to its widespread use. From food and beverages to electronics, pharmaceuticals to industrial goods, PE shrink films continue to revolutionize the packaging industry by providing impeccable protection, increasing product visibility and ensuring optimal market appeal.

Post time: Oct-11-2023