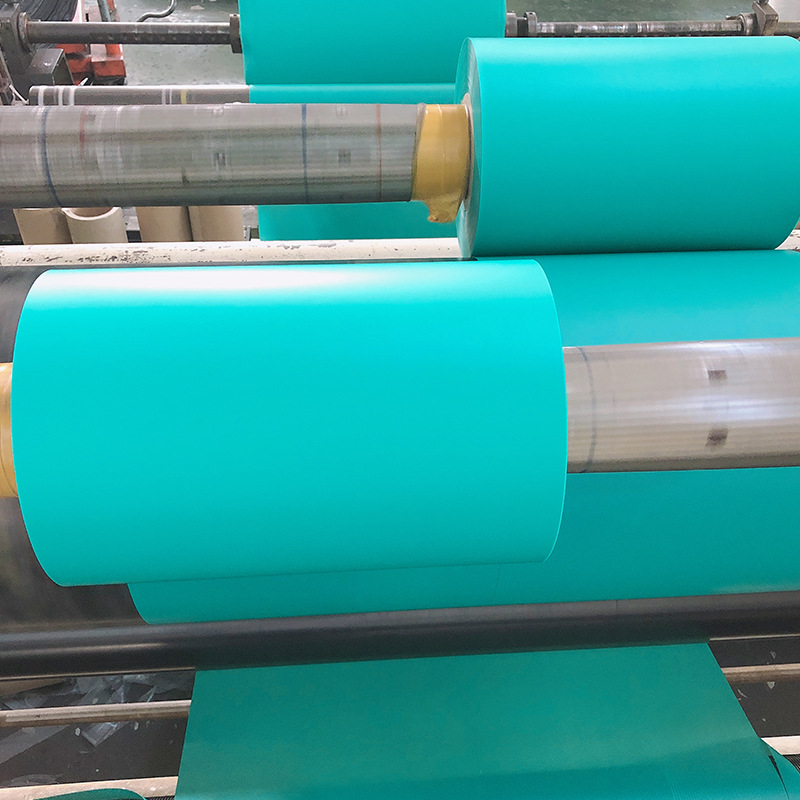

OEM/ODM Manufacturer Heat Shrink Plastic Wrap - Polyethylene blown high pressure film LDPE plastic film PE composite film – SINO

OEM/ODM Manufacturer Heat Shrink Plastic Wrap - Polyethylene blown high pressure film LDPE plastic film PE composite film – SINO Detail:

Product Description

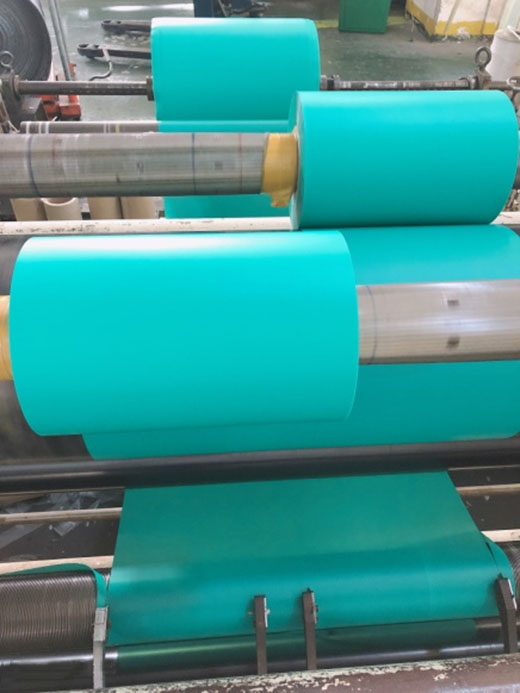

PE ordinary film is an industrial packaging film product, which has the characteristics of high tensile strength, high elongation transparency, puncture resistance, convenient packaging operation, small volume and so on. It can also improve the physical properties of products according to the different needs of customers. PE film is mainly made of several different brands of polyethylene resin by mixing and blowing, which makes the packaging neat, waterproof and isolating, and is widely used in product packaging in various industries. PE film is made of polyethylene raw materials and appropriate auxiliary materials by one-time blowing. It is characterized by good toughness, high transparency, good heat sealing, beautiful without joints, convenient transportation and storage, and small volume.

Product type: according to the needs of customers, it can be processed into cylindrical membrane, L-shaped folded membrane, single membrane, continuous roll bag or membrane, and can also be processed into cylindrical bag, flat door bag and trapezoidal bag according to the needs of customers.

Execution

Width

| Tubular film | 400-1500mm |

| Film | 20-3000mm |

Thickness

0.01-0.8mm

Cores

Paper cores with inside φ76mm and 152mm.

Plastic cores with insideφ76mm.

Outside winding diameter

Max.1200mm

Product use

Textile, building materials, chemicals, metals, manufacturing and other large-scale packaging equipment, articles, etc

Product details

Pure high-pressure raw materials have soft hand feel, high particle transparency, no white broken shadow or crease on the cutting surface, no long drawing, good toughness, easy to break after burning, high particle transparency, and the melting point is generally 160.

Application

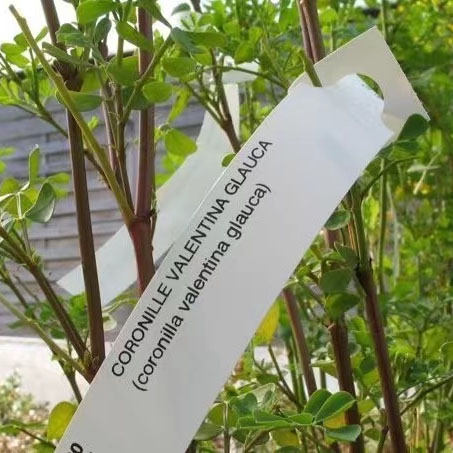

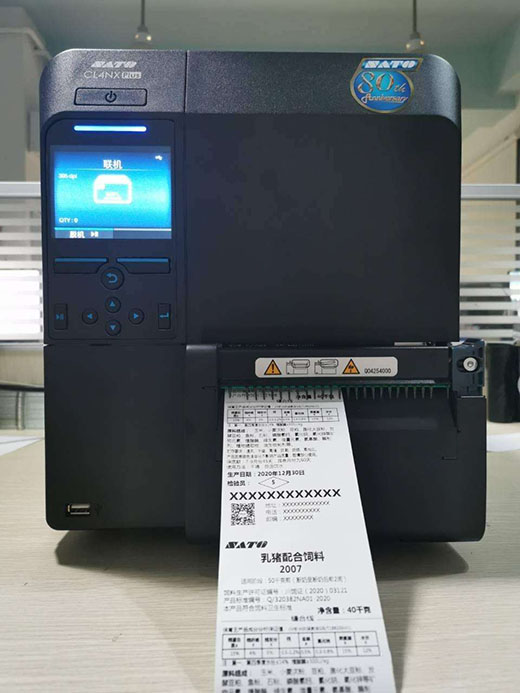

HDPE packing film

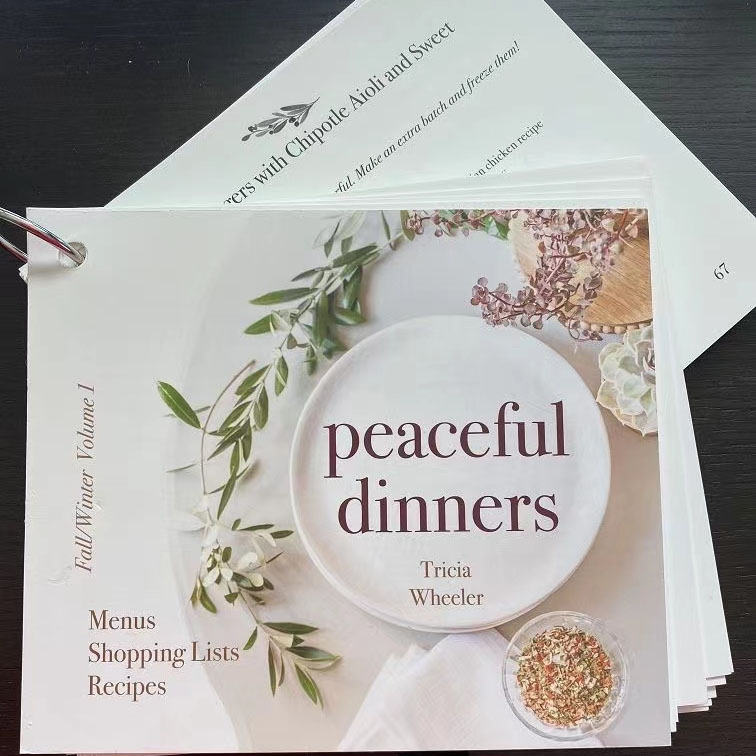

HDPE co-extruded film

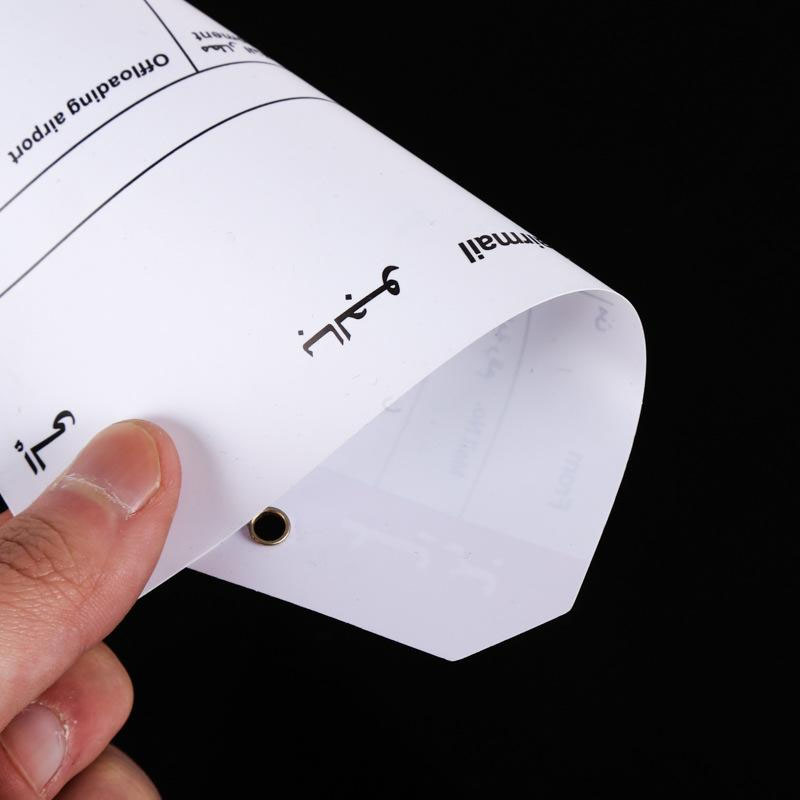

PE Label

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for OEM/ODM Manufacturer Heat Shrink Plastic Wrap - Polyethylene blown high pressure film LDPE plastic film PE composite film – SINO , The product will supply to all over the world, such as: Jamaica, The Swiss, California, Our company adheres to the spirit of "lower costs, higher quality, and making more benefits for our clients". Employing talents from the same line and adhering to the principle of "honesty, good faith, real thing and sincerity", our company hopes to gain common development with clients from both at home and abroad!

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.